Formidable Tips About Which Is Faster MOSFET Or IGBT

Funkcie IGBT Vs MOSFET

The Great Semiconductor Showdown

1. What's the fuss about speed, anyway?

Ever wondered what makes your electric car zoom or your power inverter efficiently convert energy? It all boils down to the tiny but mighty semiconductors inside. Two of the biggest players in this arena are MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) and IGBTs (Insulated Gate Bipolar Transistors). The question isn't just about which one is "better," but which one is faster for specific applications. It's like asking if a cheetah is better than an elephant; they're both amazing, but excel in very different situations. We will delve deep in it.

At their core, both MOSFETs and IGBTs are switches. They control the flow of electrical current, turning it on and off. The speed at which they can do this, their "switching speed," is crucial. Think of it like a light switch. A slow switch creates flickering, wasted energy, and a generally unpleasant experience. In power electronics, a slow switch can mean inefficiency, overheating, and potential damage to your equipment. So, speed matters. A lot.

Imagine you're trying to blink as fast as humanly possible. A MOSFET is like that super-fast blink — quick and efficient, especially at lower power levels. IGBTs, on the other hand, are like blinking with a weighted eyelid — powerful, yes, but a bit slower. That's a simplified way to look at it, of course. We will explore the nuances shortly.

Why does speed matter? In a nutshell, faster switching means less energy loss during the transition from "on" to "off" and vice versa. This leads to higher efficiency, cooler operation, and the ability to operate at higher frequencies. Higher frequencies allow for smaller and lighter designs, which is why everyone wants faster semiconductors!

MOSFETs

2. Why are MOSFETs so quick?

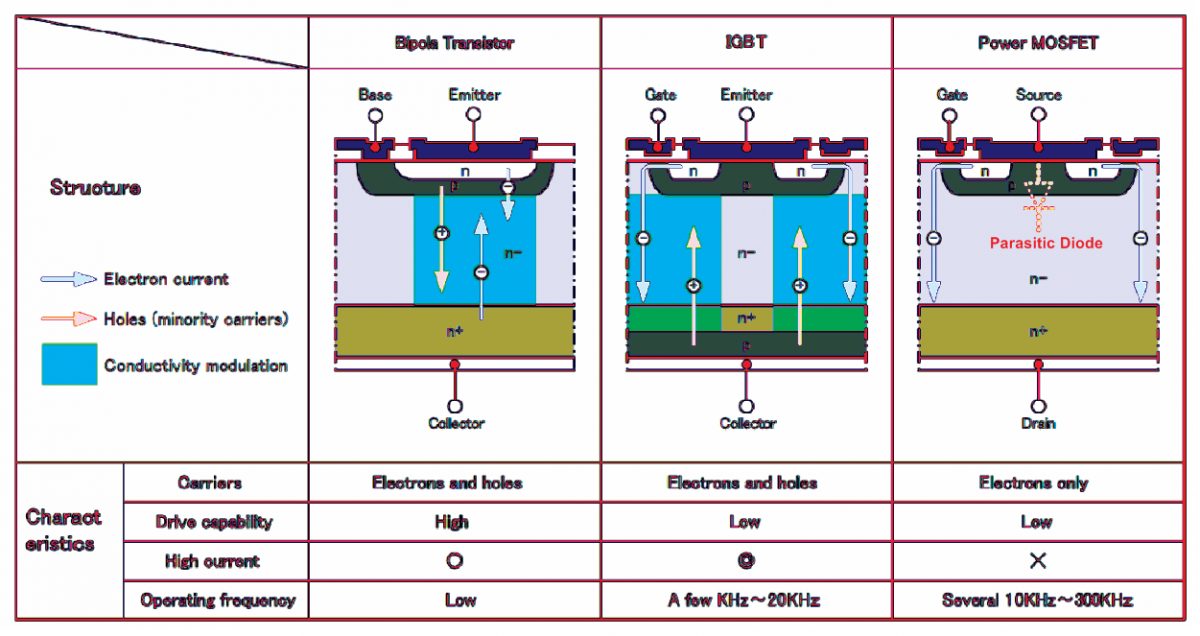

MOSFETs are known for their agility. Their speed stems from their unipolar nature — they only use one type of charge carrier (either electrons or holes) for conduction. This means there's no minority carrier injection and subsequent removal, which slows down IGBTs. It's like having a race where everyone runs in the same direction, versus one where some runners have to switch directions mid-race!

One of the key parameters that defines a MOSFET's speed is its gate capacitance. This is the amount of charge needed to turn the MOSFET on or off. Lower gate capacitance means faster switching. Modern MOSFET designs constantly strive to reduce this capacitance to achieve higher speeds. Its like reducing the weight of a race car to make it faster.

Consider applications like high-frequency DC-DC converters. These converters require extremely fast switching to minimize losses. MOSFETs are the go-to choice here because their speed allows them to operate at frequencies of hundreds of kHz or even MHz. This translates to smaller inductors and capacitors, leading to more compact and efficient power supplies. Think of your laptop charger it's small and efficient thanks to fast-switching MOSFETs inside.

However, MOSFETs arent without their limitations. As voltage and current requirements increase, their on-resistance (the resistance when the MOSFET is turned on) also increases. This leads to higher conduction losses. So, while they're fast, they're not always the best choice for very high-power applications. There's always a trade-off.

IGBTs

3. What makes IGBTs powerful, but a tad slower?

IGBTs are the workhorses of high-power electronics. They combine the best of both worlds: the high input impedance of a MOSFET and the low conduction losses of a bipolar transistor. This makes them excellent for handling high voltages and currents. Think of them as the SUVs of the semiconductor world — strong and reliable.

The downside? They are bipolar devices, meaning they rely on both electrons and holes for conduction. This leads to a phenomenon called "tail current," which occurs during turn-off. Essentially, some minority carriers (the ones that aren't the majority in the conducting region) stick around for a little bit after the gate signal is removed, causing a small current to continue flowing. This tail current slows down the switching process and leads to higher switching losses.

Imagine you're trying to stop a train. It takes a while to come to a complete halt due to its momentum. That's similar to the tail current in an IGBT. It takes some time for the current to completely stop flowing. That being said, modern IGBT designs are constantly improving to minimize this tail current and improve switching speed. New techniques like field-stop IGBTs and trench IGBTs help reduce minority carrier injection and improve turn-off characteristics.

IGBTs shine in applications like motor drives, uninterruptible power supplies (UPS), and induction heating. These applications require high voltage and current handling capabilities, and the IGBT's relatively slower switching speed is often acceptable in exchange for its robust performance and lower conduction losses at high power levels. So, while they may not be the fastest, they are undeniably strong and capable.

Igbt Transistor Vs Mosfet At Callum Winterirving Blog

MOSFET or IGBT

4. How do you pick the winner?

So, which is faster: MOSFET or IGBT? It depends! The best choice depends entirely on the application. If you need blazing fast switching speeds and are dealing with relatively lower power levels, a MOSFET is likely the better option. Think of high-frequency power supplies and small motor controls.

However, if you need to handle high voltages and currents, and switching speed is less critical, an IGBT is probably the way to go. Consider applications like large motor drives, welding machines, and high-power inverters. These applications prioritize robustness and efficiency at high power levels.

Think of it like choosing between a sports car and a pickup truck. The sports car is faster and more agile, but the pickup truck can haul heavy loads. You wouldn't use a sports car to transport a ton of bricks, and you wouldn't use a pickup truck to race around a track (well, maybe some people would!). The same principle applies to MOSFETs and IGBTs.

In many modern applications, there's even a hybrid approach. For example, you might see a combination of MOSFETs and IGBTs in the same system. MOSFETs might be used for auxiliary circuits or for handling lower power stages, while IGBTs are used for the high-power output stages. This allows you to leverage the strengths of both devices and achieve optimal performance. It's like having a toolbox with both a screwdriver and a wrench — you use the right tool for each specific task.

The Future of Power Semiconductors

5. Silicon Carbide (SiC) and Gallium Nitride (GaN) to the Rescue!

The world of power semiconductors is constantly evolving. New materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) are emerging as game-changers. These wide-bandgap semiconductors offer significantly higher switching speeds, lower on-resistance, and higher temperature operation compared to traditional silicon-based MOSFETs and IGBTs. They are effectively combining the best aspect of both worlds.

SiC MOSFETs, for example, offer switching speeds comparable to silicon MOSFETs but can handle much higher voltages and temperatures. GaN HEMTs (High Electron Mobility Transistors) are even faster, making them ideal for high-frequency applications like wireless power transfer and high-efficiency power amplifiers. Think of these new materials as the Formula 1 cars of the semiconductor world — incredibly fast and efficient, pushing the boundaries of what's possible.

These new technologies are still relatively expensive compared to silicon, but their performance benefits are undeniable. As manufacturing costs decrease, SiC and GaN are expected to become more prevalent in a wider range of applications, further blurring the lines between "fast" and "powerful." The power electronics of the future will likely be dominated by these advanced materials.

So, the debate between MOSFETs and IGBTs is far from over. While they will remain important components in various applications, the rise of SiC and GaN is poised to revolutionize the industry and usher in a new era of faster, more efficient, and more powerful power electronics. Buckle up, because the future is going to be electrifying!

Igbt Circuit Wiring Diagram

FAQ

6. Q

A: The key difference lies in their structure and how they handle current. MOSFETs are unipolar devices, relying on either electrons or holes for conduction, making them faster. IGBTs are bipolar, using both electrons and holes, which allows them to handle higher power but makes them slower. Its the trade-off between speed and power handling capability.

7. Q

A: Use an IGBT when you need to control high voltages and currents, and switching speed is not the primary concern. Applications like motor drives, UPS systems, and welding machines are ideal for IGBTs. Think of them as the heavy-duty option when raw power is needed more than lightning-fast switching.

8. Q

A: It's unlikely they will completely replace them in the near future, primarily due to cost. However, SiC and GaN are increasingly being used in applications where their superior performance justifies the higher price. As costs come down, they will likely become more widespread, especially in high-performance and high-efficiency applications. They represent the cutting edge of power semiconductor technology.