Out Of This World Tips About What Is The Best Closed Loop System

Decoding the Mystery

1. Understanding the Core Concept

Ever felt like you're chasing your tail trying to understand complex systems? Well, buckle up, because we're about to demystify the world of closed loop systems! Think of it as a thermostat controlling your home's temperature. It constantly monitors the temperature (feedback), compares it to your desired setting, and then adjusts the heating or cooling accordingly. No human intervention needed — it's a self-regulating wizard!

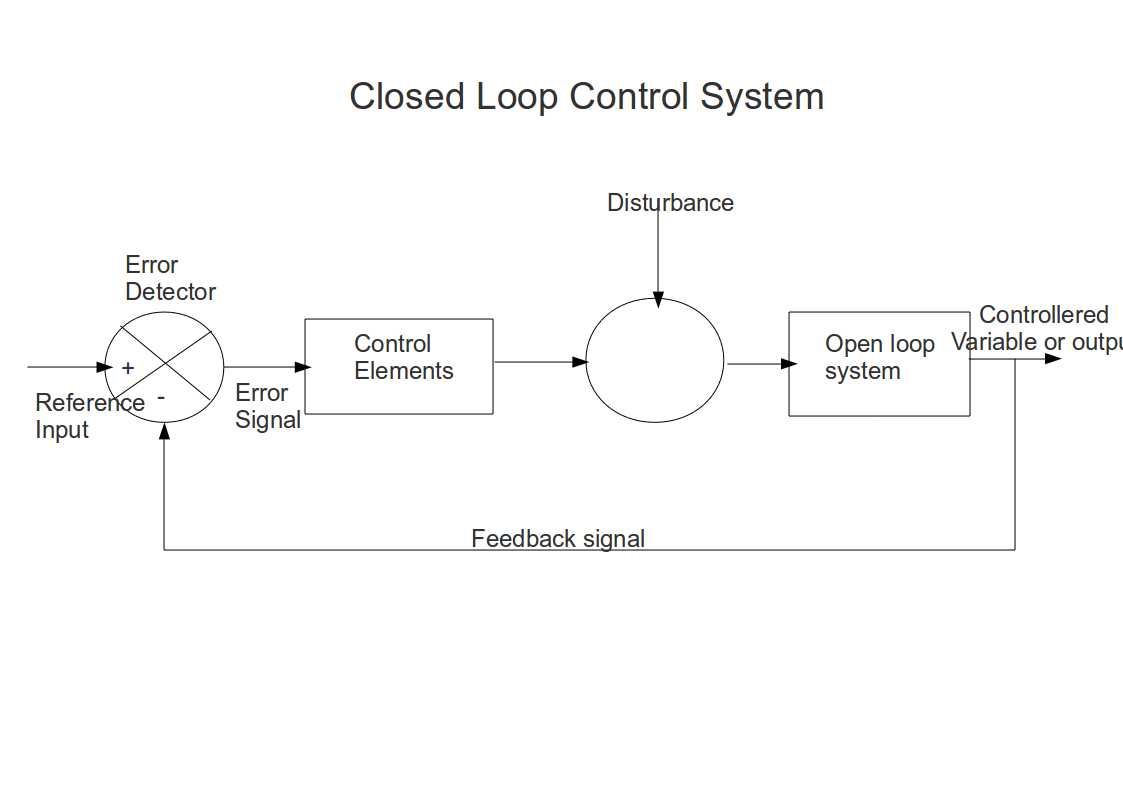

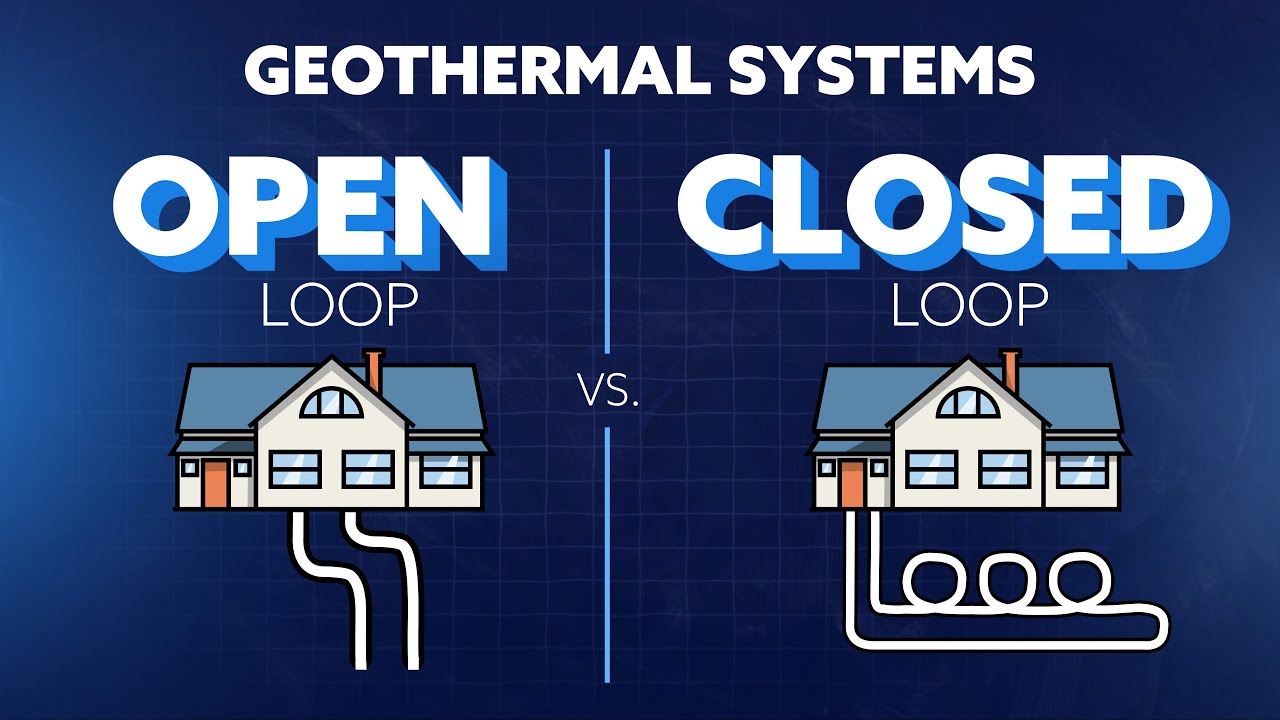

At its heart, a closed loop system is all about feedback. It's a system where the output is monitored and fed back into the system to adjust the input. This creates a continuous cycle of measurement, comparison, and correction, ensuring the system stays on track. It's like having a tiny, tireless supervisor constantly making sure things are running smoothly. Unlike open loop systems, which just blindly follow instructions without checking the results (think of a toaster that always toasts the bread for the same amount of time, regardless of how dark it gets), closed loop systems are adaptable and resilient.

Consider cruise control in your car. You set your desired speed, and the system automatically adjusts the engine's throttle to maintain that speed, even when going uphill or downhill. The car's speed is constantly monitored and compared to the set speed, and any discrepancy is corrected immediately. It's a beautiful example of a closed loop system in action, making your road trips a whole lot more relaxing. Forget those constant foot adjustments!

So, why all the fuss about closed loop systems? Well, their self-correcting nature makes them incredibly accurate and reliable. They can handle disturbances and variations in the environment without losing their effectiveness. That's why they're used in everything from industrial robots to medical devices. They're the unsung heroes of automation and control.

Test Your Skills Opening Up About Closed Loop Control Fluid Power

The Quest for "Best"

2. Defining "Best" in Context

Okay, so we want to find the "best" closed loop system. But hold on a minute! "Best" is a pretty subjective term, isn't it? What's "best" for controlling a robotic arm in a factory might be completely different from what's "best" for regulating blood sugar in a diabetic patient. The application dictates the optimal design.

When we talk about the "best" closed loop system, we need to consider a few key factors. First, what are the specific requirements of the application? What level of accuracy is needed? How quickly does the system need to respond to changes? What are the potential disturbances or variations that the system will encounter? These are critical questions to ponder.

Then, we need to think about the components of the system. What kind of sensor is being used to measure the output? What kind of controller is being used to process the feedback? What kind of actuator is being used to adjust the input? The choice of components can have a significant impact on the performance and reliability of the system. It's like choosing the right ingredients for a recipe — the quality of the ingredients directly affects the final dish.

Finally, we need to consider the cost and complexity of the system. A more complex system might offer better performance, but it might also be more expensive and harder to maintain. There's always a trade-off to be made. It's about finding the right balance between performance, cost, and complexity. Think of it as the Goldilocks principle — not too much, not too little, but just right!

Open And Closed Loop Control System

Components Under the Microscope

3. Deconstructing the Inner Workings

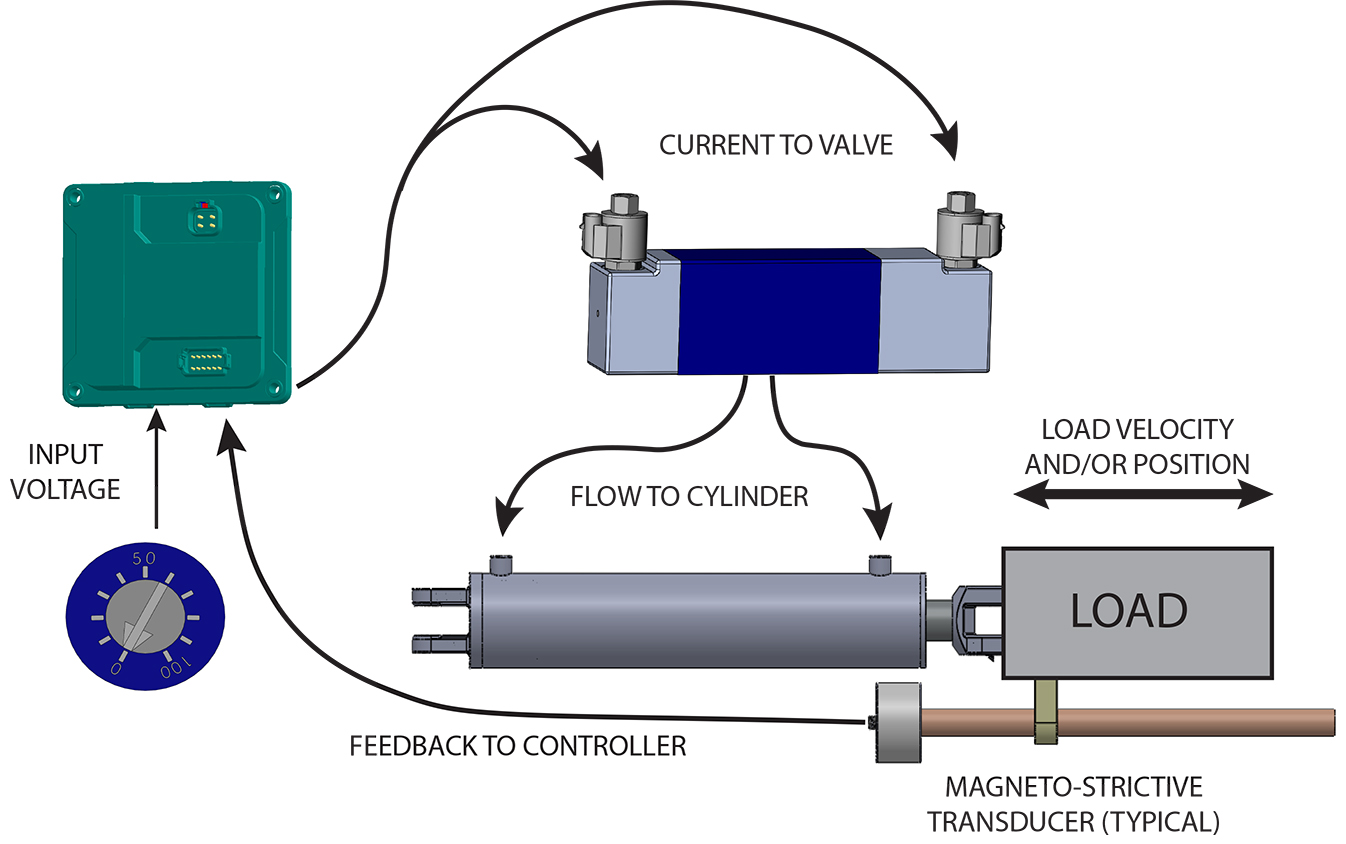

Let's dive deeper into the key components that make up a closed loop system. First up, we have sensors. These are the system's eyes and ears, responsible for measuring the output. The accuracy and reliability of the sensor are crucial, as they directly affect the accuracy of the entire system. Imagine using a blurry camera to take pictures the results wouldn't be great, right? It's the same with sensors.

Next, we have controllers. These are the brains of the operation, responsible for processing the feedback from the sensor and determining how to adjust the input. Controllers can range from simple analog circuits to sophisticated digital computers. The choice of controller depends on the complexity of the application and the required performance. Think of the controller as the conductor of an orchestra, coordinating all the instruments to create a harmonious sound.

Finally, we have actuators. These are the muscles of the system, responsible for adjusting the input based on the instructions from the controller. Actuators can be anything from electric motors to hydraulic valves. The actuator needs to be powerful enough to make the necessary adjustments and responsive enough to react quickly to changes. Picture an electric car — the actuators (motors) are essential to make it move.

The interplay between these components is critical. A high-quality sensor is useless if the controller can't process the data effectively, and a powerful actuator is useless if the sensor is providing inaccurate information. It's all about synergy. A well-designed closed loop system requires careful consideration of each component and how they interact with each other. It's like a perfectly synchronized dance — each movement complements the others to create a stunning performance.

Block Diagram Reduction Close Loop System Redu

Real-World Superstars

4. Applications Across Industries

Where can you find these clever closed loop systems at work? Everywhere! Let's explore some examples. Think of a modern airplane autopilot system. It continuously monitors the plane's altitude, heading, and speed, and makes adjustments to the control surfaces (like the rudder and ailerons) to maintain the desired flight path. It's a complex system with multiple feedback loops, ensuring a smooth and safe flight, even in turbulent conditions.

Then there's the humble refrigerator. It uses a thermostat to monitor the temperature inside the fridge and turns the compressor on or off to maintain the desired temperature. It's a simple but effective example of a closed loop system that keeps your food fresh and your drinks cold. Imagine trying to manually control the temperature of your refrigerator talk about a headache!

In the medical field, closed loop systems are used in insulin pumps for diabetic patients. These pumps continuously monitor the patient's blood sugar level and automatically administer the appropriate dose of insulin to maintain a healthy blood sugar level. This can be life-changing for people with diabetes, freeing them from the need for constant manual monitoring and injections.

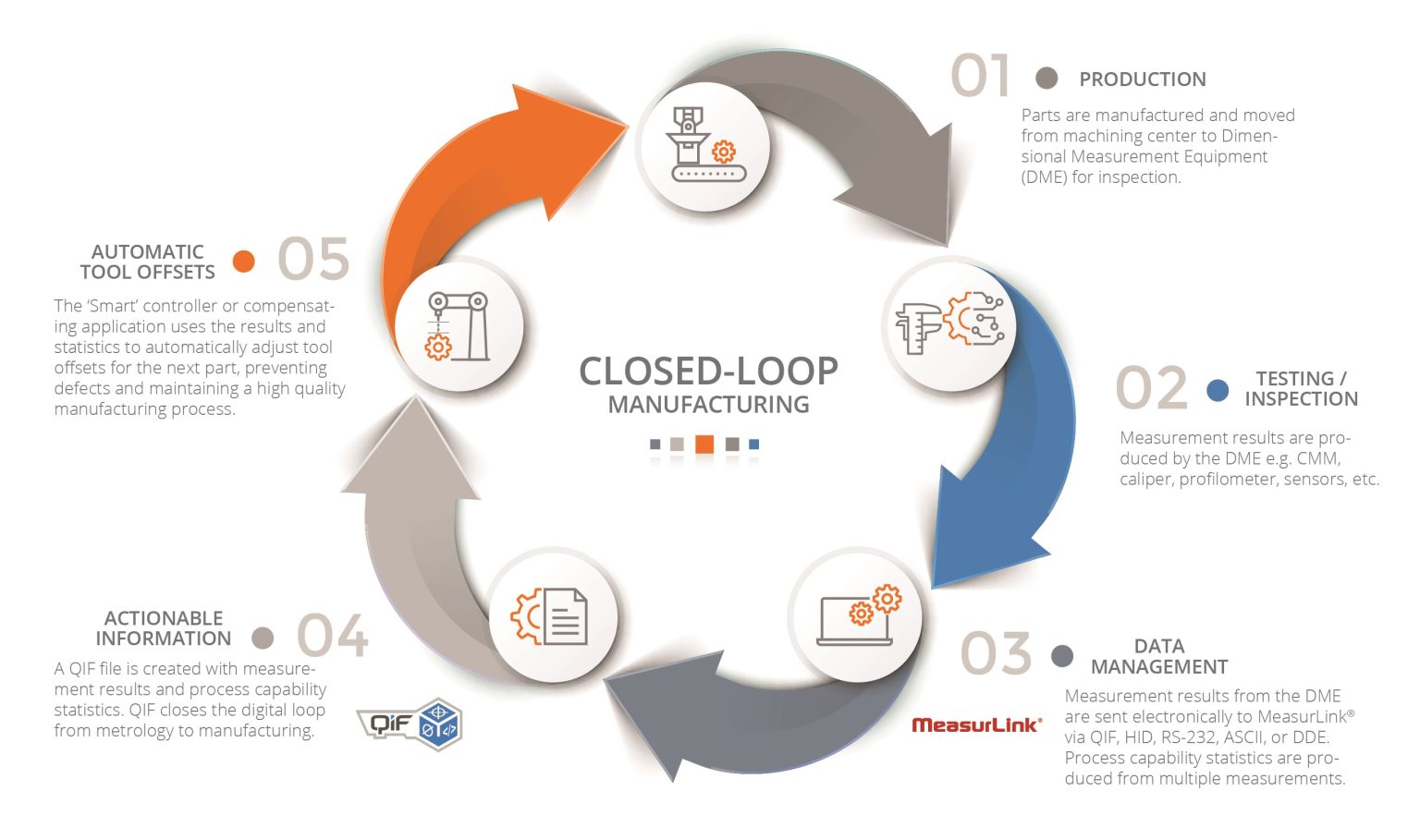

And let's not forget about the manufacturing industry. Closed loop systems are used in robotic arms to perform precise and repetitive tasks. The robot's position and orientation are constantly monitored, and adjustments are made to the motors to ensure that it follows the programmed path accurately. This allows for increased efficiency and precision in manufacturing processes. These aren't just theoretical concepts; they're the driving force behind much of the technology we rely on every day. From the cars we drive to the appliances in our homes, closed loop systems are quietly working behind the scenes to make our lives easier and more efficient.

Tuning for Success

5. Practical Tips and Considerations

Okay, so you've got your closed loop system up and running, but how do you make sure it's performing optimally? Tuning is key! This involves adjusting the parameters of the controller to achieve the desired performance characteristics. Think of it like tuning a musical instrument. You need to adjust the strings to get the right pitch and tone. It's a similar process with closed loop systems.

One common tuning technique is PID (Proportional-Integral-Derivative) control. This involves adjusting three parameters: proportional gain, integral gain, and derivative gain. The proportional gain determines how quickly the system responds to errors, the integral gain eliminates steady-state errors, and the derivative gain dampens oscillations. Finding the right combination of these parameters can be tricky, but it's essential for achieving optimal performance.

Another important consideration is stability. A closed loop system can become unstable if the feedback is too strong or if there are delays in the system. This can lead to oscillations or even runaway behavior. It's important to carefully analyze the system's stability and take steps to prevent instability. Imagine a wobbly table that threatens to collapse — you'd want to stabilize it quickly, right? Same goes for closed loop systems.

And remember, the best tuning strategy depends on the specific application and the desired performance characteristics. There's no one-size-fits-all solution. It's often necessary to experiment with different tuning techniques and parameters to find the optimal settings. It might take some trial and error, but the results are well worth the effort. A well-tuned closed loop system can significantly improve the accuracy, reliability, and efficiency of your process. So, put on your thinking cap and get tuning!

How Does A Closed Loop Geothermal System Work At Brendan David Blog

FAQ

6. Common Queries and Clarifications

Alright, time for some frequently asked questions! Let's address some of the common queries that pop up when people are grappling with closed loop systems.

Q: What's the difference between a closed loop system and an open loop system?

A: That's a great question! A closed loop system uses feedback to adjust its output, while an open loop system doesn't. Think of a clothes dryer. An open loop dryer runs for a set amount of time regardless of how dry the clothes are. A closed loop dryer, on the other hand, would sense the moisture level and stop when the clothes are dry.

Q: Are closed loop systems always better than open loop systems?

A: Not necessarily. Closed loop systems are generally more accurate and reliable, but they're also more complex and expensive. Open loop systems are simpler and cheaper, but they're less accurate and less adaptable. The choice depends on the specific application and the trade-offs you're willing to make.

Q: What are some common problems with closed loop systems?

A: Instability, oscillations, and steady-state errors are common problems. These problems can be caused by a variety of factors, such as poor tuning, sensor noise, or actuator limitations. Careful design and tuning are essential for preventing these problems.

Q: How do I choose the right sensor for my closed loop system?

A: Consider the accuracy, range, resolution, and response time of the sensor. You also need to consider the environmental conditions in which the sensor will be used. Choose a sensor that meets your specific requirements and is compatible with the other components in your system.